Cut & Etch:

Automated Image Processing

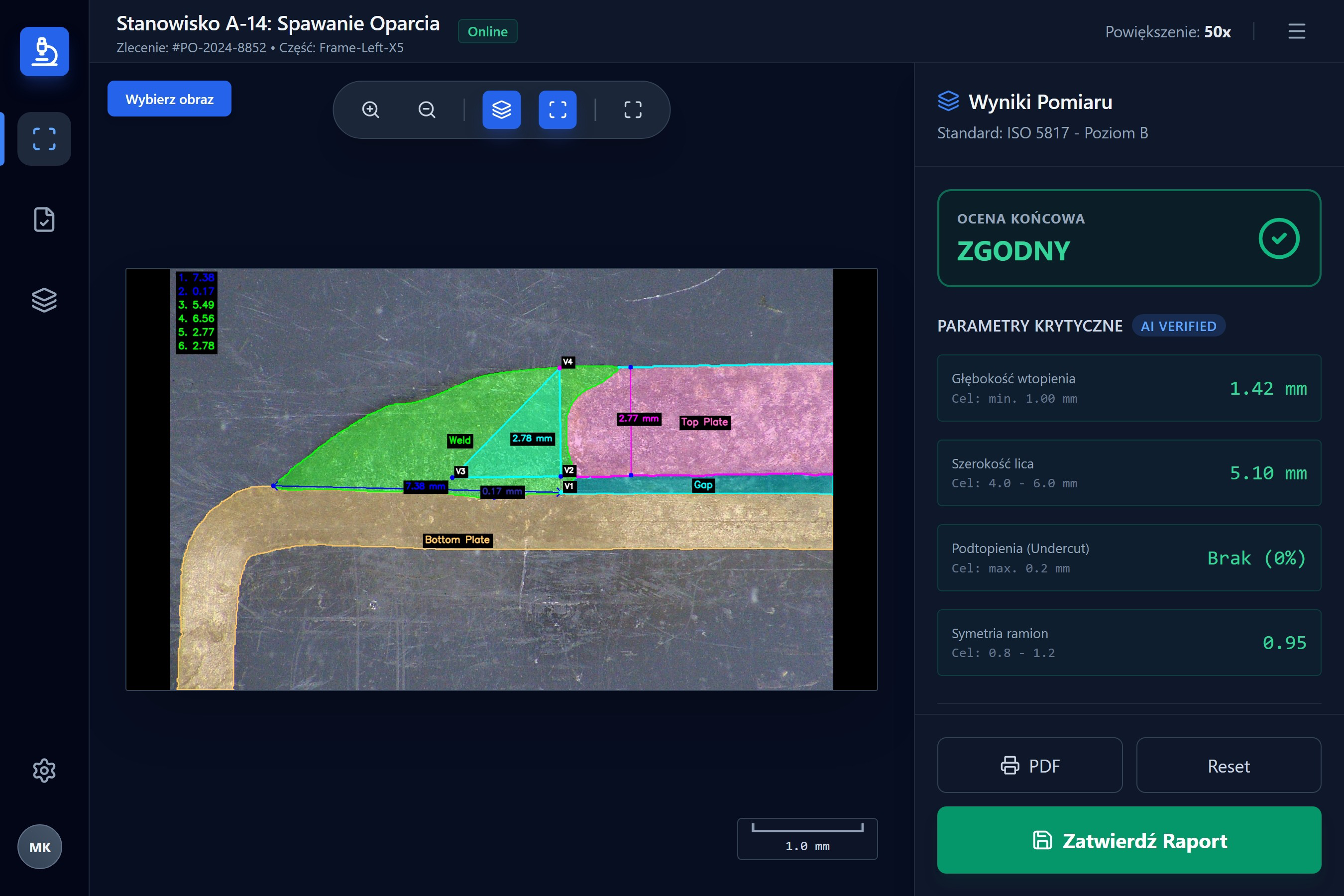

Eliminate time-consuming manual measurements. Achieve laboratory precision (IoU = 0.94) and reduce inspection time by at least 50% with our AI-driven solution, fully tailored to your industry standards.